PORTLAND, Ore. — Fairchild has been quietly perfecting microelectromechanical systems (MEMS) technologies since it first licensed

the Sandia (National Laboratories) Ultra Planar Multilevel MEMS

Technology (SUMMiT) for foundry services back in 2001. However, today

after over a decade of technological development, the company is

announcing its first Fairchild-branded MEMS using a "smart" technology

more sophisticated than SUMMiT, namely a six-axis inertial measurement

unit (IMU) with nine-axis sensor fusion algorithms.

Fairchild has continued filling out its "smart" MEMS technology

portfolio the easy way, by acquiring in 2010 the deep-trench high-aspect

ratio capabilities from Jyve--a serial entrepreneur Janusz Bryzek startup--and in 2014 by acquiring the Hollywood-proven motion-tracking software algorithms of Xsens."Fairchild knows that it is entering later a crowded space as ST, InvenSense and more recently also Bosch have established themselves solidly in the supply of IMUs and it can not offer a 'me-too' product," Jérémie Bouchaud, director and senior principal analyst, MEMS & Sensors, at IHS told EE Times in advance of the announcement. "Therefore Fairchild has leveraged the system and software know-how of Xsens acquired last year to offer a lower power consumption not only at the sensor component level but at the system level when considering the processing power."

One "smart" aspect of Fairchild's MEMS technology is its stacked die approach using state-of-the-art through-silicon vias (TSVs) instead of RF interference prone wire bonding. The Jyve-inspired MEMS die, on the bottom, and the CMOS DSP die, on the top, are stacked and packaged in the same 3.3-by-3.3-by-1 millimeter package. The Xsens-inspired XKF3 motion processing software run on the application processor but do not overburden it, since the data is already preprocessed by the IMU. The chip is also self-calibrating--no more figure-eight requests of the user by the application processor.

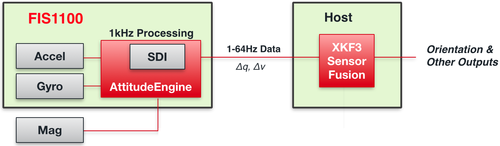

The new

FIS1100 MEMS chip from Fairchild cuts power by 10-fold by processing

1kHz raw data locally in its SDI (strap-down integration) AttitudeEngine

application specific integrated circuit (ASIC) mounted on top and

connected by through-silicon-vias to keep the package at just just

3-by-3-by-1 millimeter and communications to the host at just 1-to-64 Hz

through a 1536 byte first-in-first-out (FIFO).

(Source: Fairchild)

(Source: Fairchild)

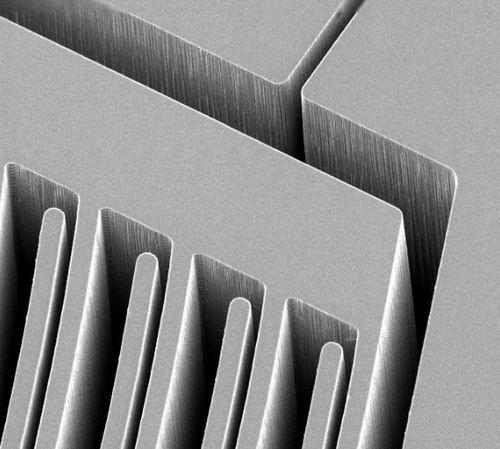

Fairchild's

MEMS is 60 microns thick using high-aspect ratio etching to produce a

low-power gyroscope that can stay one all-the-time using a single-mass

dual-cavity design for higher reliability.

(Source: Fairchild)

(Source: Fairchild)

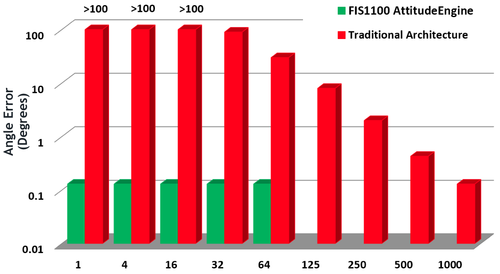

Another "smart" aspect of Fairchild's MEMS technology is that is uses the same die for both the accelerometer and the gyroscope, ending up with all six-axis on the same chip. The second part of its smart MEMS technology was to incorporate a second die it calls an SDI (for strap-down integration, and yes, I am not kidding) which is really a special purpose digital signal processor (DSP), dubbed an AttitudeEngine motion processor which starts the fusion process. By reducing the amount of raw data that needs to be sent to the application processor, the AttitudeEngine eliminates the necessity for high-frequency interrupts and allows the application processor to stay in sleep-mode longer thus extending battery life. Instead of sending the raw-data outputs from the accelerometer, gyroscope and an external magnetometer (you buy from another vendor) the AttitudeEngine only has to send low-bandwidth data to the host application processor, typically at just 1-to-64 Hz through its 1536 byte first-in-first-out (FIFO) buffer for batch processing. Once the data is on the application processor, Fairchild's Xsens XKF3 algorithms do the rest of the fusion and the motion recognition functions.

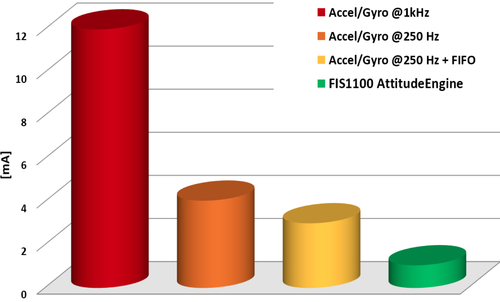

Fairchild's

stacked ASIC attitude engine reduces overall power consumption to 0.5

microAmps compared to up to 12 microamps for competitors sending raw

data to the application processor.

(Source: Fairchild)

(Source: Fairchild)

Fairchild claims to have the lowest power, lowest noise and best image stabilization algorithms in the industry. Fairchild also claims the world’s first consumer IMU with a pitch and roll accuracy of plus or minus 3 degrees and yaw accuracy of plus or minus 5 degrees, but their part has no announced design-ins yet so we will have to wait to see if the proof is in the pudding.

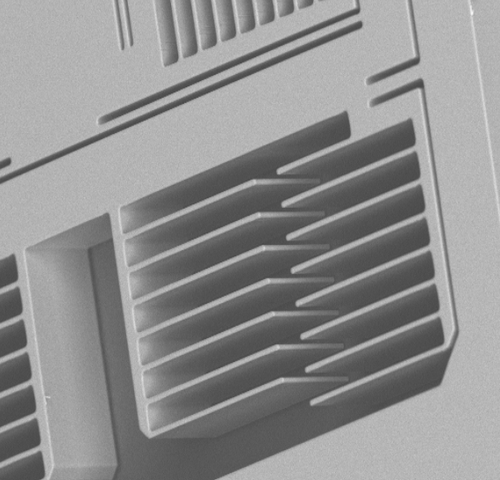

Fairchild's

accelerometer (pictured) cast on the same MEMS die as its gyroscope,

also used its super-high 60 micron aspects ratio for low power and high

accuracy.

(Source: Fairchild)

(Source: Fairchild)

Fairchild's

low-frequency connection to the application processor (1-to-64 Hz) is

just as accurate as a result of local processing of raw data in its

AttitudeEngine, as much higher speeds (1-kHz) which burdens the

application processor.

http://www.eetimes.com/document.asp?doc_id=1326879

No comments:

Post a Comment